Production

Fonderie Careglio is a foundry specializing in the die-casting of aluminum and magnesium light alloys and in the production of mass-produced products that require specific processes, treatments and finishes such as post-casting, deburring, sandblasting, tumbling, painting, heat treatment and impregnation treatments. .

Die-casting is a technological process that makes it possible to obtain extremely compact products with precise geometries that are very complex. Thanks to its ability to achieve tolerances in the order of cents this process is the most suitable melting process for the production of parts with very thin thicknesses and very high finishes, greatly reducing the cost of finishing compared to gravity.

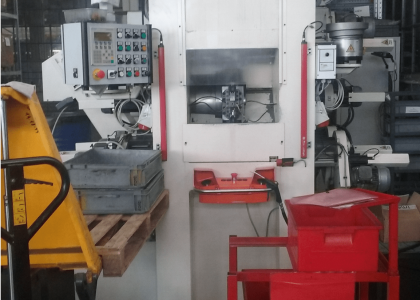

The advanced technology of the processing machinery at Fonderie Careglio allows this process to be carried out to the highest levels of precision, thus allowing a finished product of excellent quality to be obtained.

The Fonderie Careglio production area is divided into five main departments:Fuser furnaces department

- Foundry department

- Technical office and planning

- Shearing and finishing department

- Quality check